Diecasting is a crucial method in present day production, commonly made use of to produce top notch metallic parts with precision and longevity. In Malaysia, the Diecasting field has increased dramatically, steered by advancements in innovation, experienced effort, and also a tough production field. The nation has actually become a hub for Diecasting operations, offering elements to several markets including automotive, aerospace, electronic devices, as well as consumer goods. With the enhancing demand for light-weight as well as high-strength steel parts, Malaysian Diecasting companies have consistently enhanced their capacities, integrating cutting-edge development techniques to comply with international standards. The important location of Malaysia, combined along with its well-developed structure and business-friendly policies, has actually made it a popular location for Diecasting production. As sectors remain to progress, Malaysia remains at the center of preciseness Diecasting, supplying dependable options for each neighborhood and also global markets.

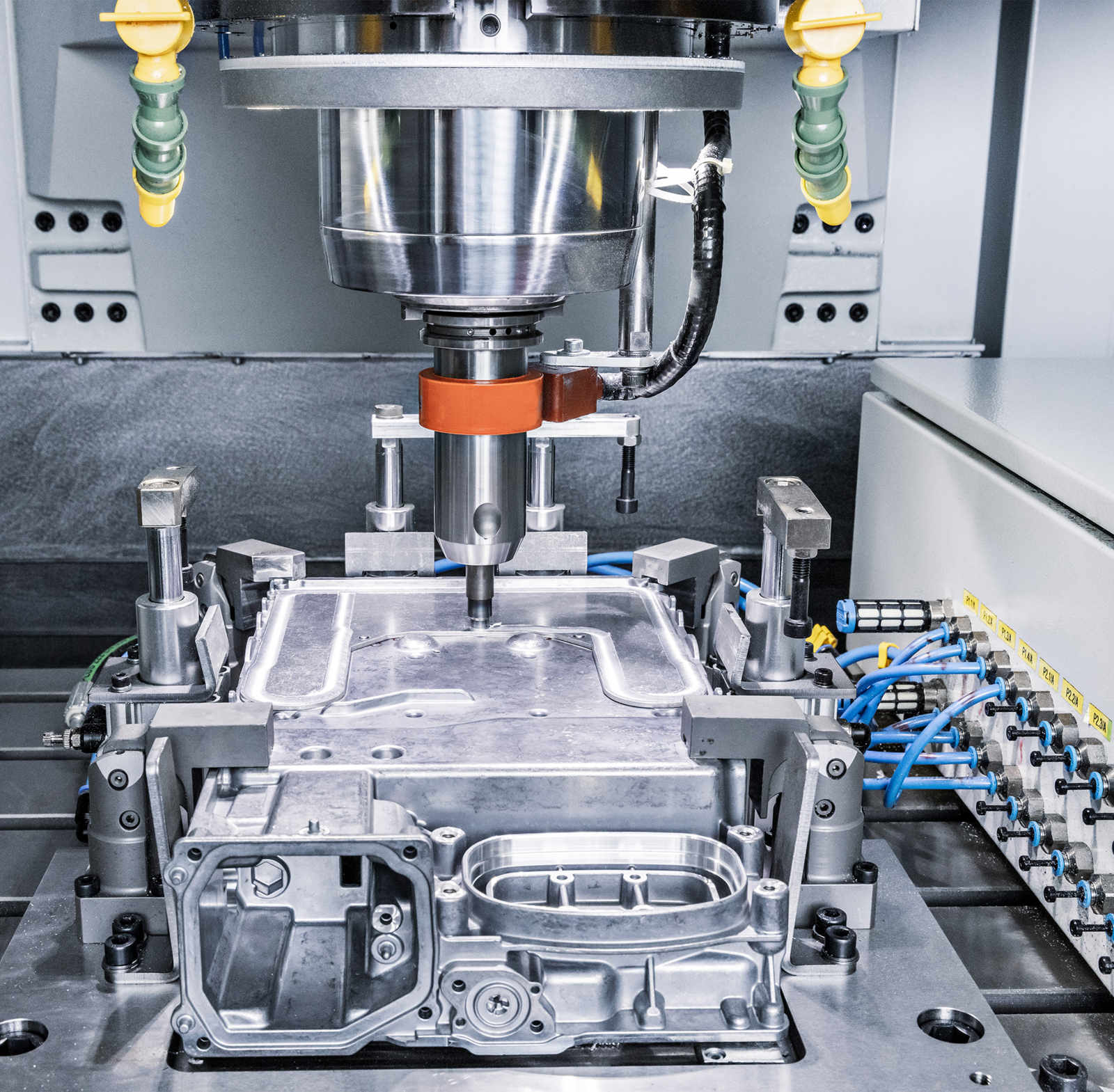

The Diecasting process in Malaysia mainly entails two principal styles: high-pressure Diecasting as well as low-pressure Diecasting. Stressful Diecasting is one of the most commonly made use of procedure, where liquified metallic is shot right into a mold cavity under higher pressure, permitting the fast development of complex and accurate components. This approach is actually commonly used in the auto and also electronic devices markets, where high reliability and also durability are actually needed. Meanwhile, low-pressure Diecasting is used for creating bigger elements along with first-rate technical residential properties, creating it best for industries such as aerospace and commercial equipment. Several Diecasting firms in Malaysia likewise deliver additional processes including CNC machining, surface therapy, and also assembly to ensure that ended up products meet the precise specifications of their clients. The continual fostering of innovative Diecasting innovations has actually enhanced effectiveness and also quality, making Malaysia a forerunner in this area.

Some of the key benefits of the Diecasting industry in Malaysia is its capacity to generate economical and top quality metal elements. The performance of the Diecasting method enables automation with very little component waste, producing it a favored choice for makers finding economical services. In addition, die-cast parts possess exceptional perspective accuracy, doing away with the necessity for substantial post-processing, which even more lowers manufacturing prices. Malaysian suppliers have additionally invested in automatic Diecasting units, improving manufacturing speed and also congruity while sustaining meticulous quality assurance procedures. The capability to generate light-weight but heavy duty components has actually supported the business’s development, particularly in fields where weight decrease plays a crucial task, such as vehicle as well as aerospace. Through constantly optimizing creation methods, Malaysia has installed on its own as a very competitive gamer in the global die designating market.

The motor vehicle field is actually one of the largest individuals of die-cast elements in Malaysia, counting on these parts for engine properties, gear box cases, architectural brackets, and also various other vital uses. As the automotive field changes in the direction of power vehicles , the need for light in weight aluminum die-cast parts has improved significantly. High pressure diecasting malaysia business have adapted to this pattern through establishing specialized blends and processes to satisfy the strict needs of EV manufacturers. Additionally, many neighborhood companies have formed alliances with international automobile brand names, offering precision-engineered die-cast elements that enrich automobile efficiency and fuel effectiveness. Along with the surge of green technology as well as maintainable manufacturing, Malaysia’s Diecasting business remains to innovate, supporting the shift to even more eco-friendly transit answers.

Past the auto sector, Diecasting in Malaysia also participates in a crucial task in the electronic devices as well as telecoms sectors. A lot of electronic units and elements demand die-cast housings and warmth drains to make certain efficient warm abandonment and protection from external factors. Along with the quick development of customer electronics as well as 5G innovation, Malaysian manufacturers have scaled up their die appointing capacities to comply with the improving demand for high-precision parts. The capacity to create complex and lightweight parts along with superior thermic conductivity has produced Malaysian Diecasting firms vital vendors for worldwide innovation companies. In addition, the government’s initiatives to advertise state-of-the-art production and also digitalization possess more built up Malaysia’s position as an ideal destination for Diecasting solutions in the electronic devices field.

The future of Diecasting in Malaysia looks encouraging, along with ongoing assets in research study, development, and computerization. As the need for high-performance steel elements grows, Malaysian producers are concentrating on lasting practices, like reprocessing light weight aluminum alloys and lessening energy usage in the development process. The assimilation of Sector 4.0 modern technologies, featuring artificial intellect as well as information analytics, is actually also assisting firms improve effectiveness, reduce defects, and improve item premium. Along with a skillful staff, strong industrial commercial infrastructure, and devotion to advancement, Malaysia continues to be a crucial player in the worldwide Diecasting sector. As more business look for lightweight and heavy duty metallic answers, the Malaysian Diecasting market is actually readied to increase further, reinforcing its own credibility and reputation as a forerunner in preciseness production.